MACKAY 1937 EXPEDITION RADIO

by Ray Robinson

INTRODUCTION

I was contacted by phone in July 2004 by John MacIllwaine, President

of the Historical Radio Society of Australia (NSW branch), and asked if

I would restore a radio for Dick Smith. The radio was used on the

Mackay expeditions. I had never heard of Mackay, but I had heard of Dick

Smith, so I said yes. Apparently it was donated to Dick Smith by the Mackay

family, and it will be displayed in the Dick Smith museum. I eventually

received the radio in 2005. I was surprised at what I saw. It was a home

made radio, with a transmitter and receiver in a plywood box. It looked horrible,

and I wondered if I had made the correct decision. It was so bad, that it

required "restoration" rather than "preservation" to prevent further deterioration.

RADIO CONDITION

The plywood case was in poor condition and coming apart,

the wooden layers separating, and peeling back in ripples. It had

little external paint left, the top was broken off, and the two opening

panels half falling off their hinges. The exterior was very dirty, but

the inside was worse as it contained a lot of red dust, some dirt, and

a fair amount of dried grass. At least it had not been stored in wet conditions.

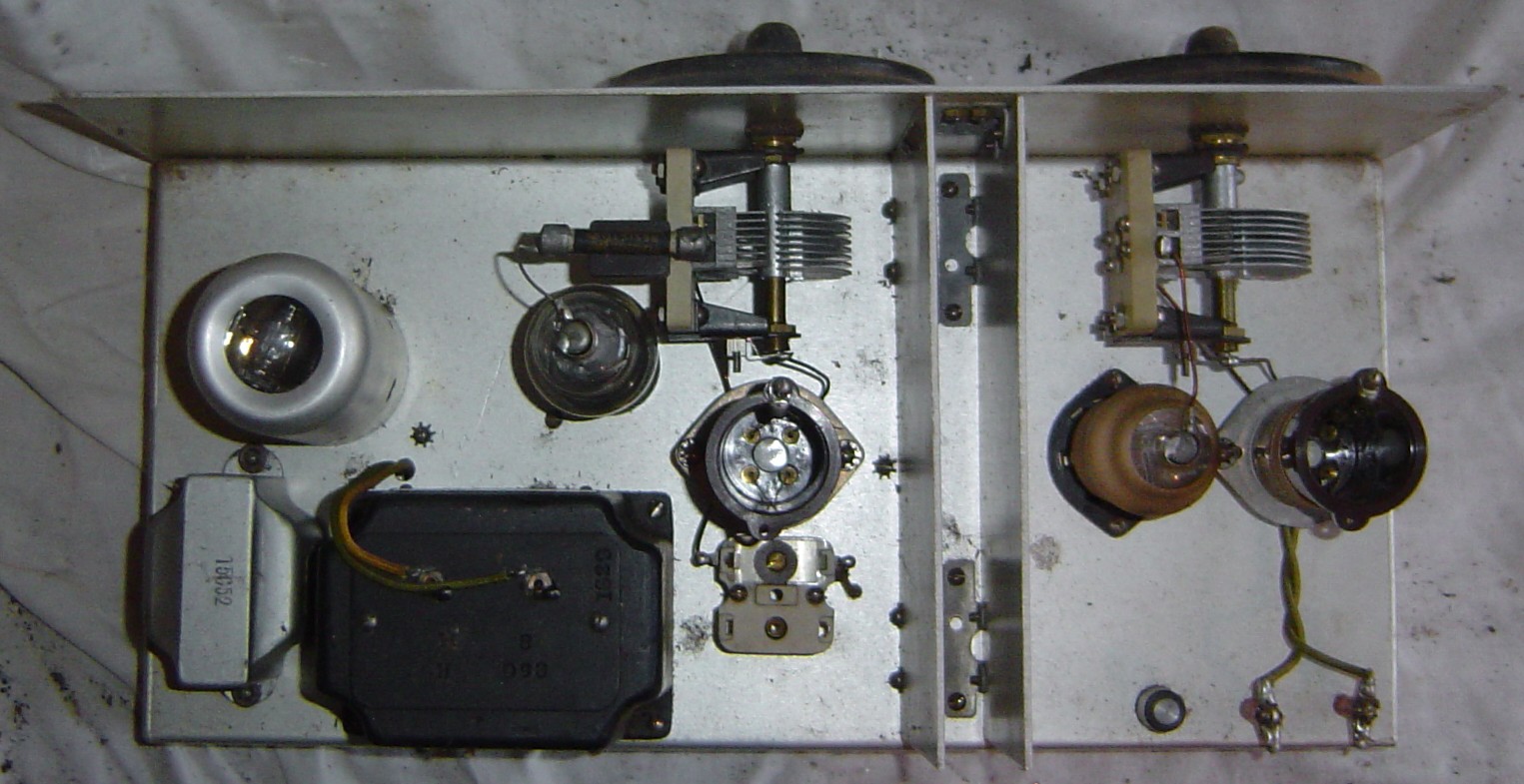

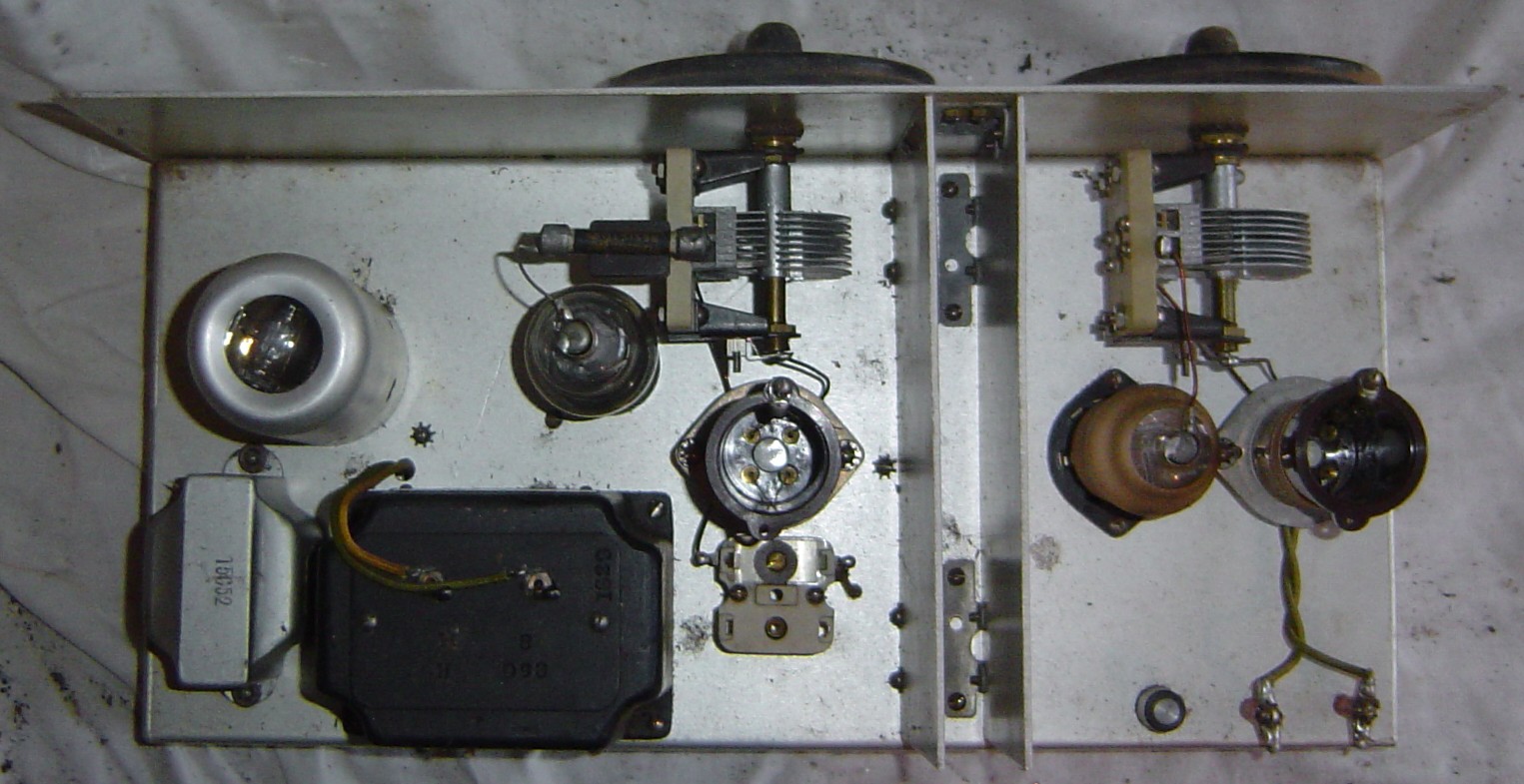

I removed the top lid, and examined the transmitter. The front panel

was awful, corroded, dials seized, and the lettering missing. The transmitter

was missing its valves, but looked complete. Upon extraction, it was

surprisingly clean underneath. The intermediate plywood shelf came out,

and revealed the receiver. It was in lovely condition, no dirt, it

had its valves, and they looked almost new. It appeared complete, and

the underside was clean. The front panel was dirty, with some labels missing,

the dials seized, and the bakelite verniers looked fragile. There were

no headphones, no power supply or batteries, no microphone, no morse key,

no transport box or case, and of course no circuits or documentation. I

sat and thought about it for a while. This was not going to be simple

and would take a fair amount of time. So I drew up a plan, restore the case

first, then the receiver, then the transmitter, and then build a power

supply. Not to be rushed, I took many photos of the outside and inside,

and drew diagrams of the wiring.

HISTORY

I began some research to find out who Mackay was, and what the radio

was used for. There was a dirty brass nameplate on the front, which read...

Short-wave Transmitter-Receiver

Designed by Don B. Knock VK2NO

Manufactured by Sterling Radio Pty. Ltd.

June 1937

So I had a starting point, the date, the designer, and the manufacturer.

Some documentation that was eventually supplied with the radio, was

provided by Dick Smith's PA (Marilyn). The typed description mentions UX199

valves, a filament control, and broadcast band radio stations, so I concluded

that this description was not for this radio set. There was a copy

of an article titled Radio on the Mackay Expedition, by

Don B. Knock, Australian Radio News, May 26, 1933, which contained a

photograph showing a transmitter, probably an airborne transmitter, as it

had 201A valves in it. The set I am restoring is a ground transmitter and

receiver. One point of interest was that the photo showed a group standing

in front of an aircraft and the caption mentions H. K. Love of the RAAF.

Love went on to form the Kingsley Radio Company which made the famous AR7

receiver in WW2 (a copy of the HRO receiver). There was another photograph

supplied, from the Sydney Morning Herald, February 1937, but it was not good

enough to show the radio. It did show a bush camp with what appeared to be

a "coffin" style receiver with a side knob, balanced on top of a pile

of stores.

Inside the radio was pinned a small piece of paper with some frequencies

scribbled on it. When I turned it over, it was a business card, which said....

Don B. Knock

14 Yanko Avenue,

Waverley NSW

phone FW 2443

Experimental Radio VK2NO

Portable Radio VK2NU

Radio Editor "The Bulletin"

252 George St.

Sydney NSW

Phone B 7971

His callsign has been reissued, so there was no help there.

The Alphabetical phone numbers, and the need to have 2 call signs will

help verify the period. I contacted the Bulletin magazine to see if they

could provide more information, but they could not help. I found a series

of articles about the life of Don Knock, thanks to several friends. An internet

search found the journals of the 1930 Mackay expedition, but this radio

was labeled 1937. I found a web site for the Power House Museum that has

Donald Mackay's bicycle, used to ride around Australia in 1901. I also found

an article titled Radio Tests in Central Australia, by H. K. Love, Listener

In, 26 July 1930. Another web site has the generator used in the aircraft

on one of the expeditions. I finally found a book by Frank Clune which was

a biography of Donald Mackay. This provided the dates and details of his

4 expeditions to map Central Australia by aeroplane, this radio being used

on the last expedition in 1937.

CASE

The plywood case was an upright design, with the receiver at the bottom,

with an enclosed shelf under it. The shelf had a hinged closing door,

affixed by brass hinges and held closed by small hooks and eye screws.

It was probably intended to store headphones, notes and pencils. Inside

it were 4 terminals and a fuse, that connect the receiver LT and HT wires

to a 4 pin socket mounted on the left hand side of the case. A battery

cable would probably plug into the socket. One terminal had a dial light

globe attached as the HT fuse. The terminals were not covered, so you could

come in contact with them, when stowing or removing the headphones. They

were live when the batteries were connected, even if the receiver was switched

off. The receiver slid down from the top, with the front panel edges engaging

with vertical slots. A better design, would have been achieved with the receiver

sliding out the front, with 2 screws at the rear to hold it in place. As

it was, the transmitter has to be removed, before the receiver can be accessed.

Above the receiver, was another enclosed shelf, with a similar opening

door. The door had the call sign VLU painted on the outside, and pencil

notes written on the back. It was probably intended to store a morse key

and a microphone. There were 4 empty screw holes in the door, which may

have been used to mount the morse key. The LT and HT wires from the transmitter,

are attached to two sockets, each having 2 pins. The socket rear terminals

were not covered, so you could come in contact with them, when accessing

the key or microphone. These were also live when the batteries are connected,

even if the transmitter was switched off. The transmitter also slips in vertically,

using slots engaging the front panel. A wire brace across the front pulls

the sides together. The top cover was hinged, to allow access to the crystal

socket for changing the transmitter frequency. When closed, the top cover

has a notch to clear the aerial wires. On the right hand side of the case

was a dual position, dual, contact ceramic knife switch, for manual change

over of the aerial from the transmitter to the receiver.

I removed the transmitter and placed it in a cardboard box and put

that aside. I also removed the receiver and placed that in another cardboard

box and put that next to the transmitter. I removed all the screws,

hinges and sockets, and placed them all in a third cardboard box. The

door from the middle shelf, has the callsign on the front and pencil notes

and frequencies on the back. I got some tracing paper, and traced the VLU

legend, so that I can repaint it later. I used a spray can of clear lacquer to

protect the hand written notes on the rear of the panel.

I sanded all the rough wood. It had particularly bad warping

on the bottom. The wood where all the hinges were attached was cracked, split

and broken. I used clamps and glue to hold the broken and warped wooden parts

together. I painted all the wood with pink primer to prepare and preserved

the wood. I then painted the final two coats with grey oil based paint,

which matched the original colour. The original hardware, the hinges,

hooks and eyes, were all rusty and needed replacing.

They looked as though they were originally made from brass plated steel.

I managed to find some new brass hinges and screws, and some new eyes for

the latches, but no hooks. I finally had to spray the original hooks

with gold paint, to reuse them. I screwed on the hinges, attached the front

opening panels and the hinged top, then added the latches. I made up

a new VLU legend on a computer, scaled it to size using the tracing paper,

printed it on Decal water slide transfer paper, and applied it. I then spayed

it with clear lacquer to protect it. The wooden case was now complete.

RECEIVER

I started work on receiver. It was in good condition, the underside

was very clean. The top side was good, no doubt due to being housed within

the cabinet undisturbed, and covered. This meant that it was difficult

for dirt to get in, but even so, there was some grass inside. The components

were clean, and the cotton covered wires were in good condition. The front

panel was corroded, the dials had red dirt in them, they were seized,

and missing the knobs. The front panel was also missing half the labels.

I removed the dials for cleaning. One tuning capacitor was loose.

I adjusted the friction, being careful to avoid a short circuit. I tightened

several screws as all the coils were loose. The coil wire windings were

cotton covered wire, but not lacquered. I considered fixing/sealing

them with lacquer, but decided not to. This was a restoration, so any

attempt to improve the radio was to be avoided. I traced out the circuit,

and it appeared to be a regenerative detector (valve type 15), with

one AF amplifier (valve type 1D4), and one RF amplifier (valve type KF3).

I checked the resistors and they were all within tolerance. I looked

up the valve characteristics and they had 2 volt filaments. I applied

2 volts DC, and switched ON, the filaments drew current, which was a

good sign, as it meant no one had burnt them out. The AF amplifier used

a speaker transformer as a choke, and had a phone jack, with a capacitor

from the AF amplifier plate, which means it required high impedance

headphones. I located a pair of suitable period headphones. I applied

DC to the HT and negative wires (it uses back bias), and slowly wound

it up to 90 volts. I heard some noise when adjusting the tuning capacitors

(they needed some lubrication). The set oscillated when I turned the

reaction control up, which was a good sign, it meant that at least

two valves were working. I connected an aerial, but not much happened. I

advanced the HT to 125 volts, and heard a station. The controls were

touchy without the vernier drives attached, and the set was also microphonic,

which is common with filament valves. I used a signal generator to determine

the frequency coverage, which was 4.75 to 13.7 mhz. I lubricated the capacitors

and potentiometers. It was amazing that the receiver worked, with its original

paper capacitors and resistors.

I cleaned the vernier dials and they came up nicely. There

was some wear on the bakelite around the knob shaft so they were a little

sloppy. I was donated 2 knobs by a friend which were close to what should

be there. The centre bakelite cover for the main shaft had gone brittle

with age. I removed the front panel and polished it on a buffing wheel,

but could not remove the deep pitting and corrosion. Another approach

was necessary. I cleaned the front panel with warm detergent, then etched

it with sodium hydroxide (Draino drain cleaner). I then anodized the

front panel in sulfuric acid (battery acid) at about 2 amps. The panel came

up nicely, but the pitting was emphasised greatly. So that was no good. I

then sanded it with steel wool in one direction only, to remove the anodizing,

and then sprayed clear lacquer on it. That was the best I could do,

as I did not want to replace the front panel. It had a long score mark

(probably for marking up during manufacture) and a couple of elongated holes.

This probably means that this was a "one off" model and possibly made

to a time schedule. It will look as though it has been out in the outback.

I reassembled the receiver and put in a cardboard box for protection.

TRANSMITTER

I started work on the transmitter and cleaned the dirt from

the chassis. I removed the front panel, and cleaned the dirt off with detergent.

I scrubbed it with wire wool and lacquered it. I did the same with the

brass nameplate, and then cleaned and wire wooled the brass meter bezels.

The four ORMOND dials were corroded and seized. I disassembled them

(each dial had 11 parts), and cleaned and lightly oiled the bushes

and bearings and knobs.

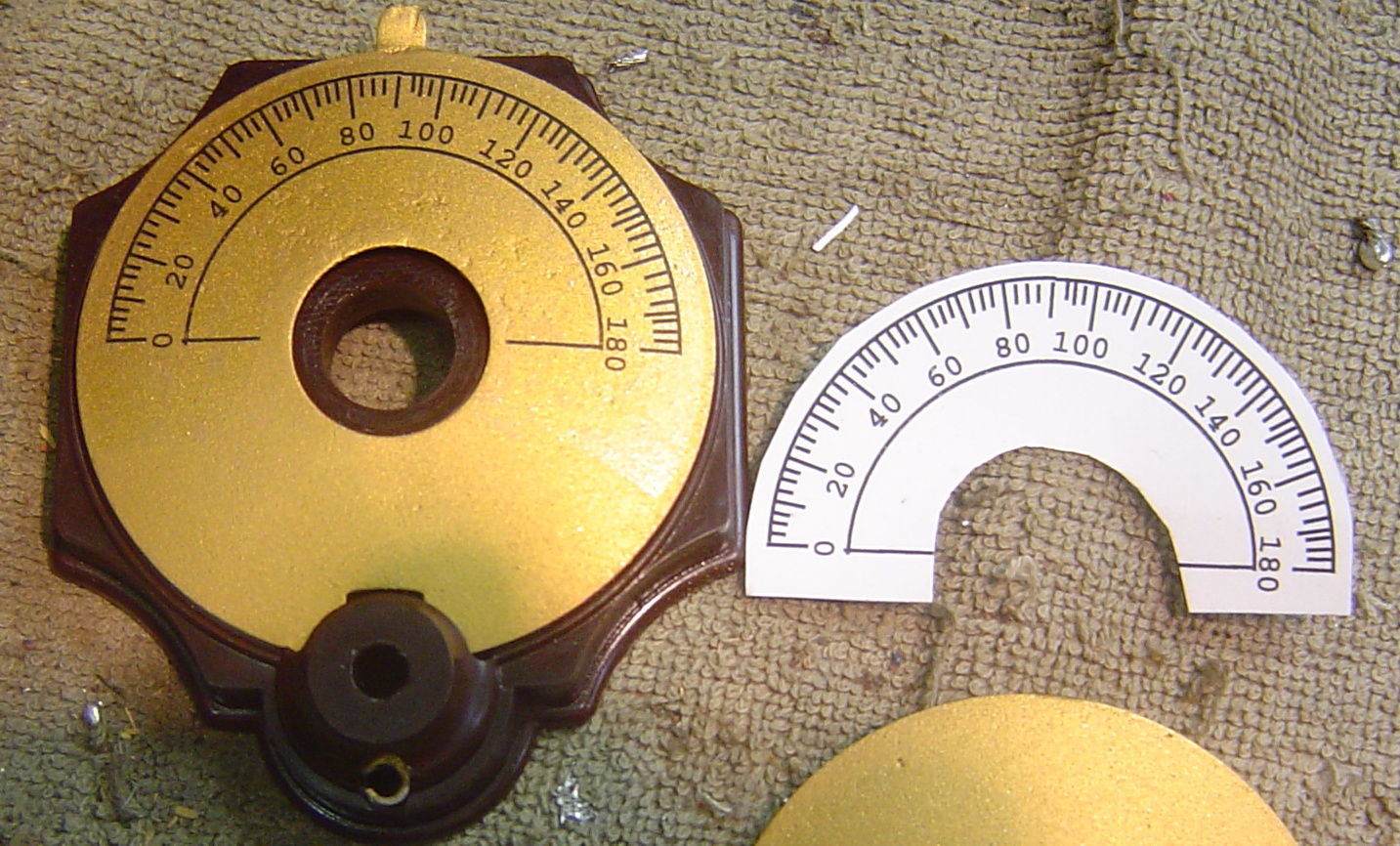

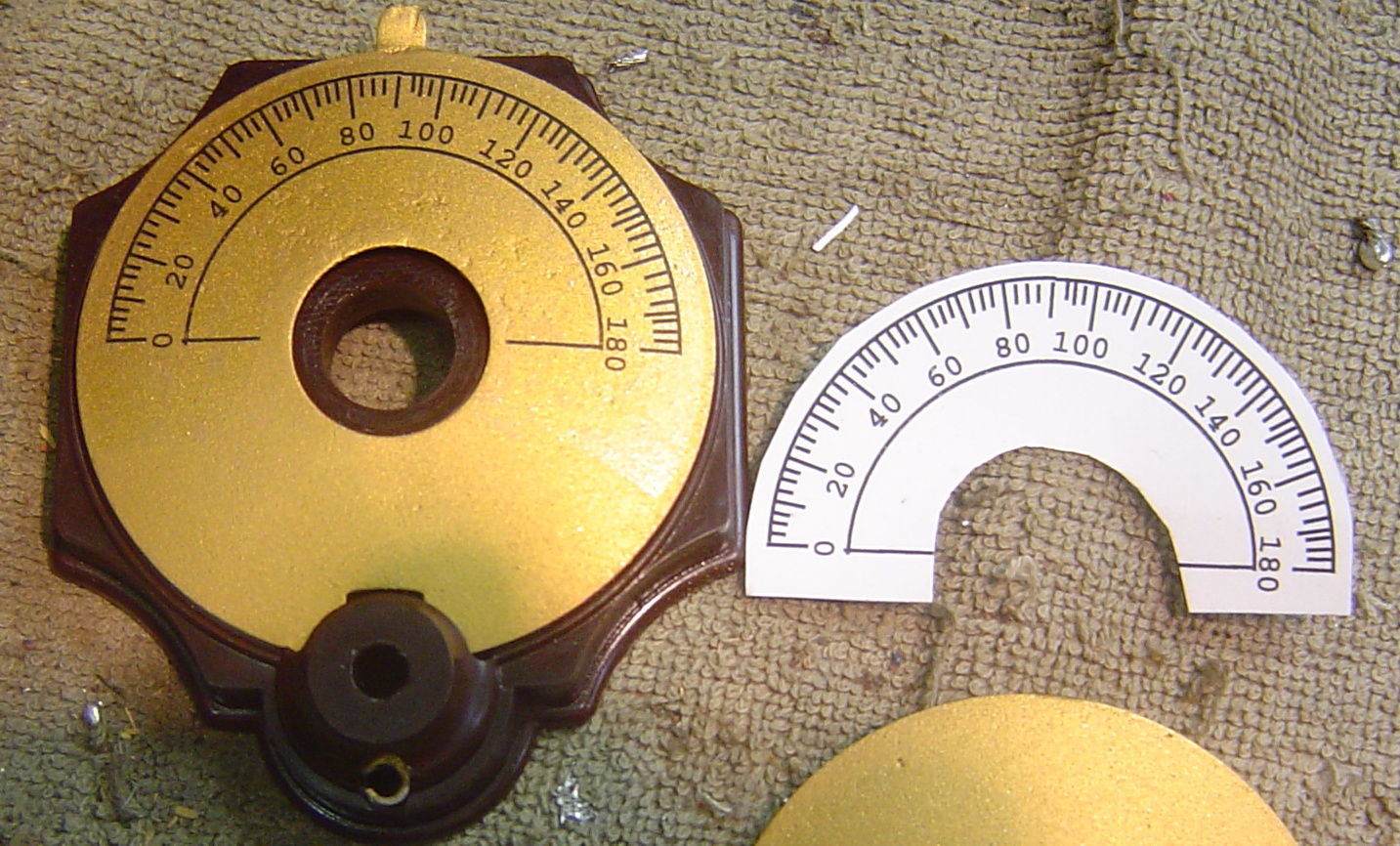

The dial graduations were silk screen black lines and numbers

(0-180) on a gold painted scale. The scale was corroded and the markings

hardly legible. I sanded the dials scales smooth, and painted them

with gold paint. I made a new dial scale on the computer, and laser printed

it on to "Waterslide Decal" paper (about $1.30 a sheet). I cut

these out with scissors, soaked them in water, and applied them. I made

them semicircular, not an annulus, as the scale is convex, and the

decal needs to bend a little. I then applied a thin coat of lacquer to protect

it, not too thickly, as it will attempt to dissolve the decal. Two thin

coats were required.

I reassembled the dials, then mounted them on the front panel.

The rusty screws were cleaned, and the heads lacquered. Any spare holes

were filled with a screw. The front panel had small labels, which were

affixed near each control. Some were missing. They appeared to be a metalised

label with a photographic or inked legend. They looked like Scotchcal

labels but that 3M product was not available then and is no longer available

now. There is a new product called "Adressotak", which is a metalised

adhesive backed label, available in silver or gold, and comes in A4 sheet

size (about $3.75 per sheet). I prepared the artwork on a computer and printed

it on a laser printer then cut it out with scissors, peeled off the backing,

and the self adhesive label just glued on. I copied the original legends,

and made guesses as to what the missing ones might have been. It was

a good result, closely matching the originals.

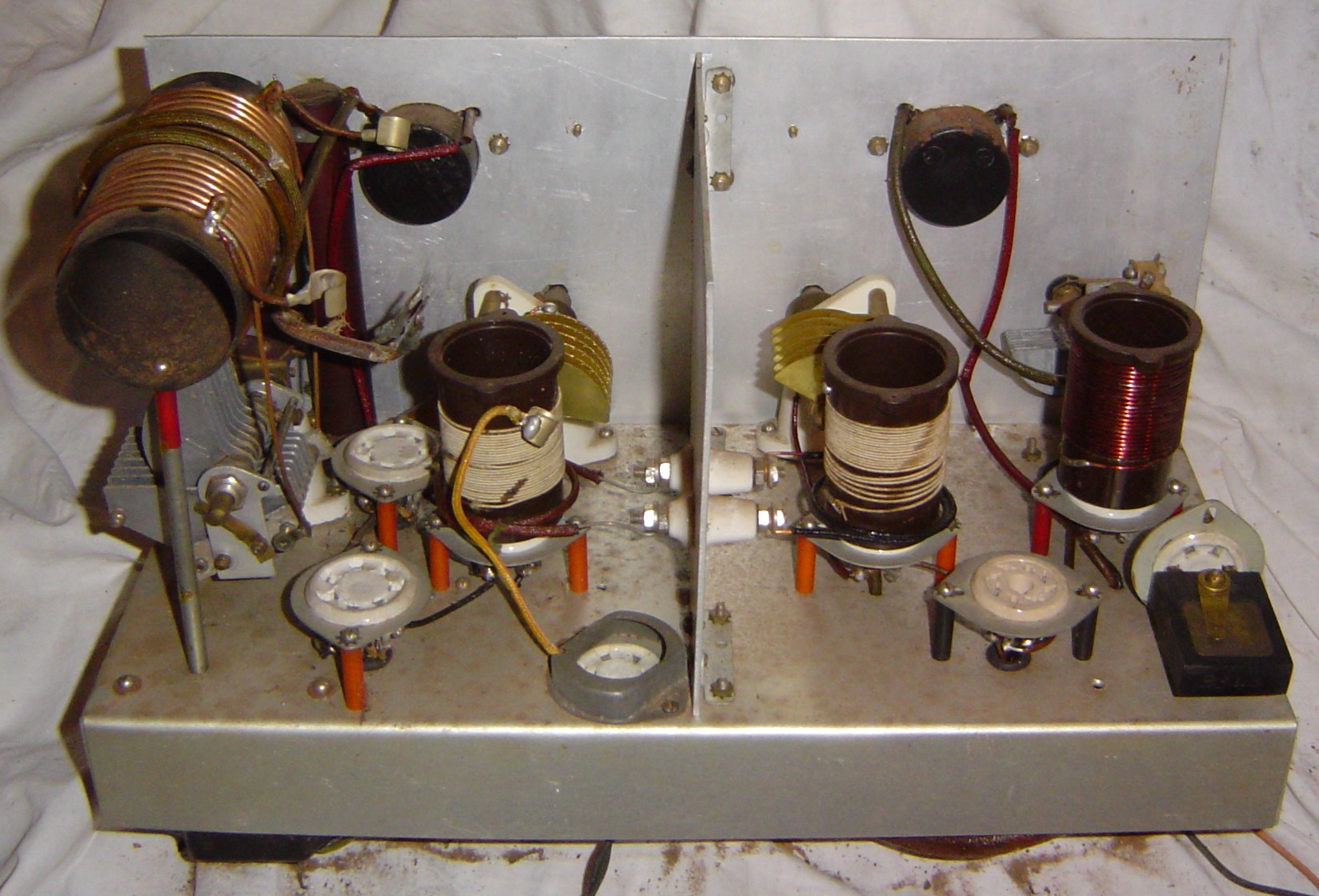

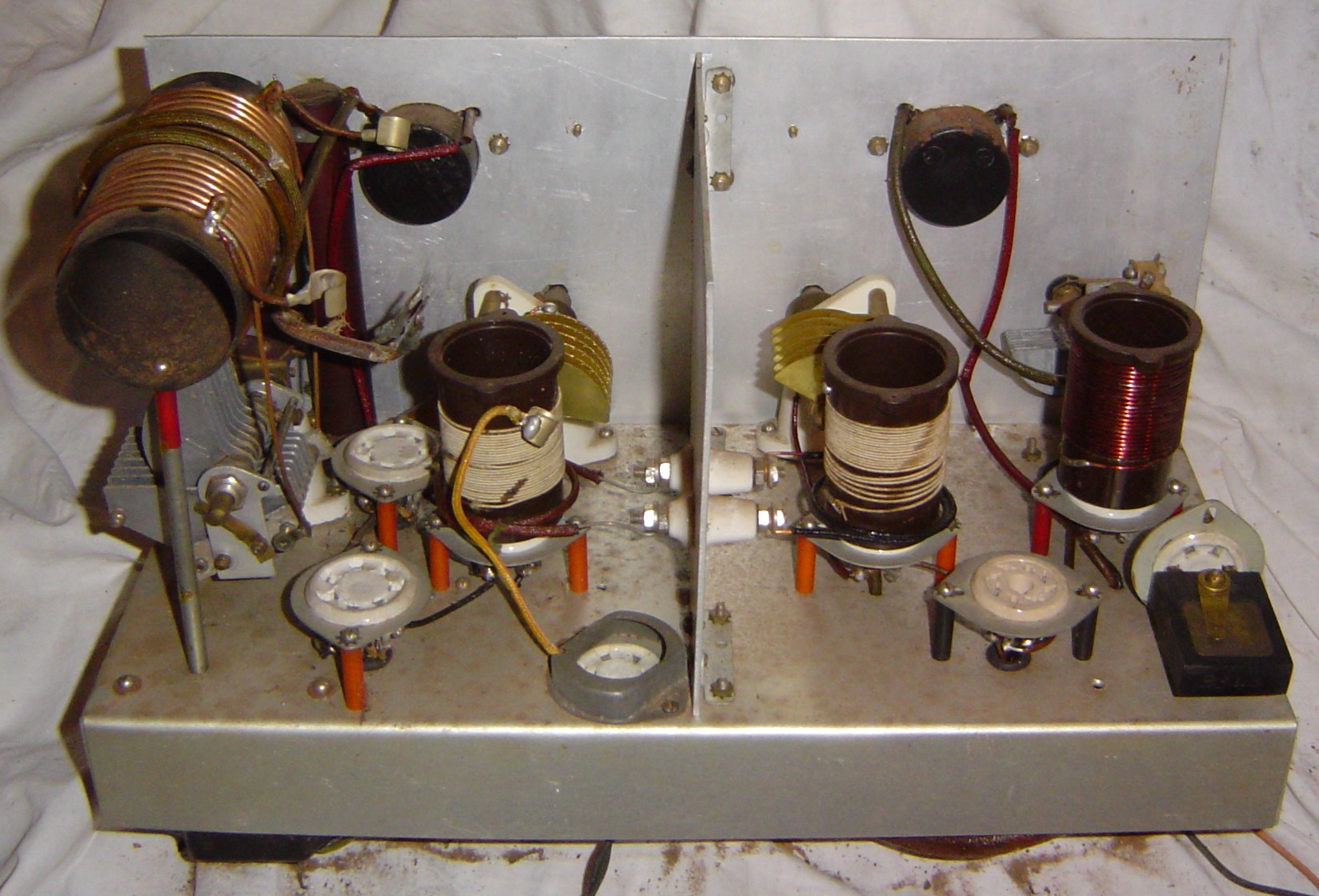

I traced out the transmitter circuit. It appeared to be a pentode

crystal oscillator, with a plate current meter for tuning. The

power amplifier was two valves in push-pull. There was a single valve as

the modulator. The physical construction was generally good, some parts were

well made and constructed. The oscillator section was shielded and nicely

laid out and spaced. The coils plug in on 4 pin bases, one for the oscillator

cathode, and one for the oscillator plate. The oscillator cathode coil

was enamel wire covered in lacquer. The plate coil was made of cotton

covered wire, but the original enameled wire leads to the base were still

visible, which means that it was originally enameled wire, and this

had been cut off and it had been rewound. The grid coil for the power

amplifier has had the same treatment. The coupling from the oscillator plate

coil was a 2 turn link winding, which feeds through the shield to the

power amplifier section. The grid coil had an identical link. The links

were nicely made and laced. There were several extra holes in chassis which

were not used. Many holes had not been de-burred after drilling. There

were also some construction scratches. The tank coil was mounted on tall

posts, and was wobbly and flimsy. The oscillator and power amplifier sockets

were on short posts, mounted above the chassis so they would have good shielding

from the circuitry below. The modulator valve was mounted in a hole

in the chassis. The power amplifier valves were too close to the tank coil,

were actually resting against it. The tall chassis mounted electrolytic

capacitor, the older wet type, was also too close. It had dried out and

the label had fallen off, so I glued it back on. The tank tuning capacitor,

was a different type to the other three tuning capacitors. It looked

second hand and had some bent plates, so perhaps it had been changed.

The tank coil connections to the capacitor were loose, and one had no nut.

The shaft wiper and the shaft coupling both looked home made. One of the

coil mounting tags was sticking out, as though it was added later or

was the wrong size. The capacitor shaft was too close and rubbed on the tall

electrolytic capacitor. The HT bypass capacitor is a long tube with wax sealed

ends, held to the front panel by clamps. It looked home made. I measured

it and it was only 25 pF, very strange. I turned the chassis over, to see

where the lower pigtail passed through the chassis. It went through a rough

un-burred hole, but was floating, that is, not connected to anything!

It should have been earthed. This appears to have been a construction

error. Perhaps it was touching the hole when it was first made. Maybe

it was intermittent, which may explain the modified appearance of the

tank components. When I connected it to earth, the capacitor value read

as 0.25 uF, which was much better. However, it did not change the resonant

frequency of the tank coil, which was 5.2 to 11.1 mHz. The oscillator cathode

coil frequency was 3.4 to 9.8 mHz, which was indicated on my Grid Dip

Oscillator (GDO). The oscillator plate coil did not dip at all. There was

a place on the coil where two wires were twisted together, so I soldered

them, and it then dipped at 6.0 to 10.0 mHz. The power amplifier grid

coil was 5.0 to 8 mHz.

The transmitter had no valves, so I had to identify the types.

The Power amplifier used a 7 pin UX base, with a plate top cap. The 807

valve has 5 pins, so it was not that type. The 1625 has 7 pins, but

was made after 1937. That left the 802 valve, which matched the application

and physical dimensions. This meant that the other valves had to be 6.3

volt filament types. The oscillator valve was octal based, and the

pin connections matched the 6V6, 6F6, and 6L6. The 6V6 was lower power

and was available in 1937. The modulator valve had a 6 pin UX base, a

6.3 volt filament, had a grid top cap, and had to be an audio power

valve. The only candidate was the 89. I had none so I ordered one from

Melbourne. I had the other three valves in my junk box.

The modulator valve was cramped into one corner. The microphone

transformer and modulation transformer were mounted under the chassis,

but poked down too far, such that the wooden partition below the transmitter

had two square rough cut-outs for them. It all looked like an after-thought.

Perhaps it was added later. I placed a 10 uF 600v electrolytic capacitor

across the defunct large tubular vertical electrolytic capacitor, and

hid it under the chassis. I removed the modulator cathode bypass capacitor,

and put a new 25 uF 50 volt electrolytic capacitor hidden inside the

old cardboard case.

It was time to test the transmitter. I found an

early morse key for the transmitter. There was no crystal in the holder. It

was a bakelite holder, with two brass plates held down with a spring clamp.

The slab of quartz was missing so I added an FT243 crystal with alligator

clips. I connected a 12 volt 25 watt light globe to the aerial terminals.

I powered up the valve heaters with 6.3 volts AC, and they all seemed

to glow appropriately. I then applied 100 volts DC, and the plate

current meters showed a little deflection. There appeared to be no short

circuits. I slowly increased the voltage in 50 volt steps to 300 volts.

I monitored the plate current and dipped the meters with the four

tuning controls. The meters are very lively and would benefit from some

damping. They wobble all over the place so finding the dip is difficult

and time consuming. The light globe was glowing. It all appeared to

be working, and the morse key keyed the transmitter properly. Wonderful!

Then the PA plate current began to rise, for no apparent reason, so I switched

everything off.

POWER SUPPLY

The radio uses an external power supply, connected by cables

to sockets on the case. The receiver has a 5 pin UX type female

socket. I found two suitable plugs from my junk box and plaited a cable

from some old style cotton covered wire, and then attached the 5 pins plugs

to each end. The transmitter uses two 2 pin male sockets on the case,

of a type that I have not seen before. I examined my junk box

and found two plugs that were a close fit, but with a wrong pin spacing.

I removed the pins and elongated the holes, such that the pins matched,

and then glued them in place. One has a key, so that it can only be

inserted the correct way, and it also can not be confused with the

other. I plaited a cable from cotton covered wire, to connect these two

plugs to a 4 pin UX plug. The keyed plug is the 500 volts DC and the

unkeyed plug is the 6.3 volts AC.

There was no power supply provided with the radio, and there

was no indication what it might be. I guessed that the receiver would

operate from batteries. The filament battery would probably be a single

lead acid cell providing 2 volts at 0.5 amps. The high tension would

probably be a dry battery providing 135 volts at approximately 15 ma.

The transmitter requires 6.3 volts at 2.5 amps, so this would probably

be three lead acid cells. The high tension would be somewhere between

400 and 600 volts at about 100 mA, which would probably be supplied

by a 6 volt dynamotor or petrol generator. I decided to build a mains power

supply, to generate these voltages.

I used an old instrument case to build the power supply. It had

2 sockets on the front, a 4 pin socket for the transmitter, and 5 pin

socket for the receiver. It had separate mains ON switches, fuses, indicator

lamps, and output sockets, so that each supply can be used independently.

I painted the power supply front panel the same colour as the radio. I finished

constructing the receiver filament supply. It consisted of a transformer,

which had a 240 volts AC input and a multi tapped 15 volt secondary.

I then adjusted the taps, to get the correct output voltage. It used a diode

bridge rectifier, with the filtering done by a choke with 2 large capacitors.

The finished receiver power supply had too much hum. There was not enough

filtering on the DC filament supply, as the choke and capacitor filter were

insufficient. I used two high power diodes in series, to provide a 2 volt

zener regulator. This heated up after about 5 minutes, and the 2 volts

drooped to 1.8 volts, but this appeared to make no difference to the receiver.

The hum was still just audible but not obtrusive.

I finished the receiver high tension circuit. This is another transformer

identical to the other, but connected in reverse, so that the 240 volt input

winding is the secondary. Then I connected the 15 volt output of the first

transformer to the 6 volt tap on the second (reversed) transformer, thus

achieving a 120 volt secondary. It used a diode bridge rectifier with a choke

filter, 2 capacitors, and a 10k 2 watt bleed resistor. The receiver was

now not working! It had failed since my initial testing. The reaction coil

had a tap which was twisted together, and this had gone open circuit.

I soldered it, and the radio worked well on the new power supply.

I began on the transmitter power supply. I used an old large

mains transformer, suitable for field coil speakers. It had a 385 volts

aside secondary, and a 6.3 volt filament winding. When rectified with silicon

diodes, and a choke and filter capacitors, it produced 500 volts DC,

which will probably under run the final valves a little. There was also 27k

5 watt bleed resistor. I used the 6.3 volts AC winding for the transmitter

valve heaters. I powered up the transmitter, and the power supply appeared

to function properly, until one of the power supply filter capacitors went

short circuit. I replaced it. The transmitter with 500 volts DC, appeared

to work well into a light globe dummy load. The current meters did not read

full scale, indicating that it may have been designed for 600 volts DC,

as the 802 data sheet suggested. The oscillator tuning control could pull

the crystal a little, and it would also oscillate without the crystal, so

it could be used as a VFO. The oscillator meter was dipped with the second

control. The third control is used to provide drive to the final and is tuned

for maximum plate current. The 4th control is the tank circuit and dips

the final meter. After 5 minutes, the plate current began to rise again,

so I turned it off. The long bakelite cylinder behind the panel was hot.

This was the final HT bypass capacitor. I melted the wax off, and the internals

were removed. It consisted of two 0.5 uF 600v capacitors in series. They

were replaced by one 0.25 uF 1000v capacitor hidden inside the original

Bakelite tube, with the ends sealed in wax. This had fixed the problem.

The transmitter appeared quite reliable. The spectrum analyser showed that

it generated several harmonics, but if the transmitter was tuned properley,

the harmonics were 40 dB below the fundamentals amplitude.

The circuits were hand drawn, so I decided to use Protel to draw

them neatly. Protel only had transistor, IC (Integrated Circuit), and passive

components, so I had to design some valve building blocks for the library.

I also made some older style tuning capacitor symbols and a high voltage

transformer, with filament windings. Then I drew the circuits for the receiver,

transmitter, and power supply.

Receiver circuit.

Transmitter circuit.

Power supply circuit.

TESTING

Drawing the circuits clearly, made me realise that the microphone picked

up voltage from the transmitter heater circuit. This meant that it must

be a carbon microphone, but of what type? I had no 1937 vintage microphones

suitable, so I used a temporary one. I also realised that the transmitter

heater voltage should be DC instead of the 6.3 volts AC that the power supply

was delivering. I had tried to use passive components in the power supply,

but it was now obvious I needed to use a regulator IC. I realised that I

had to redesign the transmitter heater power supply. At the same time, I

decided to redesign the receiver filament supply, so I used an LM317 regulator

IC which can supply 1 amp, and set it up for 2 volts DC. The receiver drew

0.5 amps. For the transmitter heater supply, I used an LM350K regulator IC

in a TO-3 case, and bolted it to the chassis for a heat sink. I set it up

for 3 amps at 6 volts DC. The transmitter drew 2.65 amps. There was not

enough voltage available from the 6.3 volts AC winding on the transformer,

so I connected the 5 volts AC winding up as well. There was a problem here,

as the transformer has an internally earthed centre tap, so I connected

them in an unbalanced series mode. The new heater power supply appeared

to work well.

I tried the receiver with the new DC filament supply, and it now had

no "mains" hum, but had a little "grid" hum. This was bearable. It

was very microphonic, with occasional loud clicks. It also dropped in and

out of regeneration suddenly.

I tried the transmitter with the new DC heater supply and it worked

well. The voltage sagged when the transmitters cold heaters were turned

on, but then it reached the operating voltage as they warmed up. The oscillator

worked well, it worked too well, it oscillated, even without a crystal.

I wondered if the leads were too long as I had the crystal clipped in with

alligator clips. I pulled the FT-243 crystal apart, took out the quartz

slab, and put it into the original holder. There was no difference, it still

oscillated anywhere and pulled with the oscillator tuning. The tuned circuits

only tuned from 5 to 10 mhz, so I assumed the crystal would be in this range,

and I was using a 7.025 mhz for the 40 meter amateur band. Then I realised

my mistake. The holder had 3340 scratched on it, and the second front panel

control was labeled DOUBLER. I should be using a crystal at half the transmit

frequency! I found a 3.540 mhz crystal from my junk box, put it in with

alligator clips, and the VFO was suddenly perfectly stable, it tuned up

nicely, and transmitted on 7.080 mhz

The morse key is in the final amplifier cathodes, so the oscillator

does not pull or chirp. When tuned, the transmitter lit up a car light

globe as a dummy load. I tried a WW2 carbon microphone and it modulated

the carrier, but it looked a little ragged on the oscilloscope. It should

have been better than that.

I was not completely happy with the operation of the transmitter. I had

identified the connections, the valves, drawn the circuit, but there was something

still eluding me. The transmitter had 8 wires protruding from the bottom,

2 went to the HT power supply, 2 went to the heater supply, and 2 went to

the morse key. There were 2 wires that I could not determine a function for.

The transmitter functioned on CW without them being connected to anything.

They went to the final valve suppressor grid, through a modulation transformer,

so they had something to do with that. Perhaps they could have been connected

to a plug then plugged into the microphone jack. This would make the audio

amplifier oscillate and produce MCW. That would justify the reversing

switch which reverses the wires. But why was this not done internally? Why

were the wires so long, the ends are bare, not soldered, and look as though

they are for connecting to terminals. I connected the 2 unknown wires to a

jack plug, plugged it into the mic jack, and switched the switch back and

forth, while watching the modulation, it would not oscillate.

My 40 meter aerial had fallen down in the summer storms, so on one

of the few fine days on the weekend, I put it back up again. I tuned up

the aerial on 7.080 mhz and gave a few calls on CW and phone, but received

no replies. I tried again a few days later, with Ian VK2ZIO listening

at Kurrajong. He heard me despite the competing Chinese RADAR signals. A

wonderful effort for an old transmitter. He couldn't hear my voice signal

though, just the carrier, so more tests were needed.

On-Air recording (6mb wav file)

On-Air recording (6mb wav file)

The transmitter was incorrectly labeled, as I had made a guess from

the switch function, and what labels remained. The two right hand switches

were labeled from right to left, OFF (switch) CW, (switch) PHONE (microphone

gain control). The right hand switch turned the heaters on and off,

so I changed CW to ON, and added a FIL VOLTS label above it. I was

still not sure what that second reversing switch did, but it was labeled

PHONE, so I left it that way. My wattmeter said 10 watts, but I thought

it should be capable of more that that. I read the 802 (final valve) data

sheet, trying to figure out what it could deliver. The maximum ratings

are, plate 500 volts DC at 30 ma, screen 200 volts DC at 28 ma, plate

dissipation 10 watts. My power supply delivers 530 volts DC and when tuned

shows 50 ma for the 2 valves, so this appeared correct, but it also implied

that power output should be greater than 10 watts. The data sheet also

gave grid bias and suppresser grid conditions for class A, B, and C, and

for audio, RF, CW and telephony. The "grid leak" bias resistor was

wired as recommended. The suppresser grid could have 2 different connections,

depending on use. It could be grounded or connected to cathode as is normal.

Reading further, it could also have -40 volts DC on it for telephony, or

+40 volts DC on it for CW. Finally, the use of those 2 wires and the switch

became apparent. It needed a bias battery and used the reversing switch for

CW and PHONE. I redesigned the power supply and added a 40 volt floating

supply, coming to the front panel on 2 terminals. The 2 bias wires were attached

to the terminals. I tried the transmitter into the wattmeter and the power

output was now 30 watts on CW and 10 watts on PHONE. The modulation envelope

was considerably better.

CONCLUSION

The radio seems to be a one off design, with the modulator added as an after

thought. The design would be better, with a 6 pin socket for the transmitter

power input, instead of a 4 pin socket and 2 floating wires. I took the radio

to the Central Coast Field Day on the 18th February 2007 and displayed

it there. I had planned to have it operating but I had not completed

the power supply at that time. It looked very nice. A helicopter arrived

and Dick Smith came over to have a look at the radio. He seemed happy with

the restoration effort.

When I had finally finished the power supply, I packed it up, and Marilyn

delivered the radio back to Dick Smith in April 2008. He donated it to the

Powerhouse museum, in Sydney.

REFERENCES:

Last of The Australian Explorers, Frank Clune, Angus and Robertson,

1942.

Radio on the Mackay Expedition, Don B. Knock, Australian Radio

News, May 26, 1933, pp 7, 39.

Photograph of transmitter, Knock, Love, Neale, and Robertson,

with Gull.

Photograph of Wireless Station at Docker Creek, Sydney Morning

Herald, 29 June 1933.

Visible are two people, generator, and wireless receiver.

Mackay Expedition emergency hand cranked generator, Radiold

website.

(http://www.radiold.com/radios/radrare/radrare03.htm)

Radio Tests in Central Australia, H. K. Love, Listener In,

26 July 1930, pp 18, 19, 58.

also on the web at.....

(http://www.radiold.com/radios/radrare/listener_in01.jpg)

(http://www.radiold.com/radios/radrare/listener_in02.jpg)

(http://www.radiold.com/radios/radrare/listener_in03.jpg)

Dux bicycle, ridden around Australia by Donald Mackay, Power

House Museum, Registration number B583.

(http://www.powerhousemuseum.com/collection/)

Mackay Expedition 1930, Philip Crosby Morrison Guide to Records,

Series 11

(http://www.austehc.unimelb.edu.au/guides/morr/MORS0011.htm)

(http://www.asap.unimelb.edu.au/bsparcs/biogs/P000657b.htm)

The Mackay Aerial Survey Expedition, Central Australia,

May-June 1930, The Geographical Journal, Vol. 84, No.6 (Dec 1934),

pp 511-514.

(http://www.jstor.org/view/00167398/ap020504/02a00050/0)

D. Mackay papers (State Library of New South Wales).

Australian Dictionary of Biography

(http://www.adb.online.anu.edu.au/biogs/A100284b.htm)

Sydney Morning Herald, 1 Feb 1937

Papers received with 1937 transmitter and receiver, in possession

of Dick Smith VK2DIK.

Donald Mackay (1870-1958) Australian Explorer and

Pioneer Wireless User, Ray Robinson

Copyright Ray Robinson

end